Bushing Current Transformers offer tailored solutions for high-voltage equipment, providing protection and reliable readings in power distribution systems.

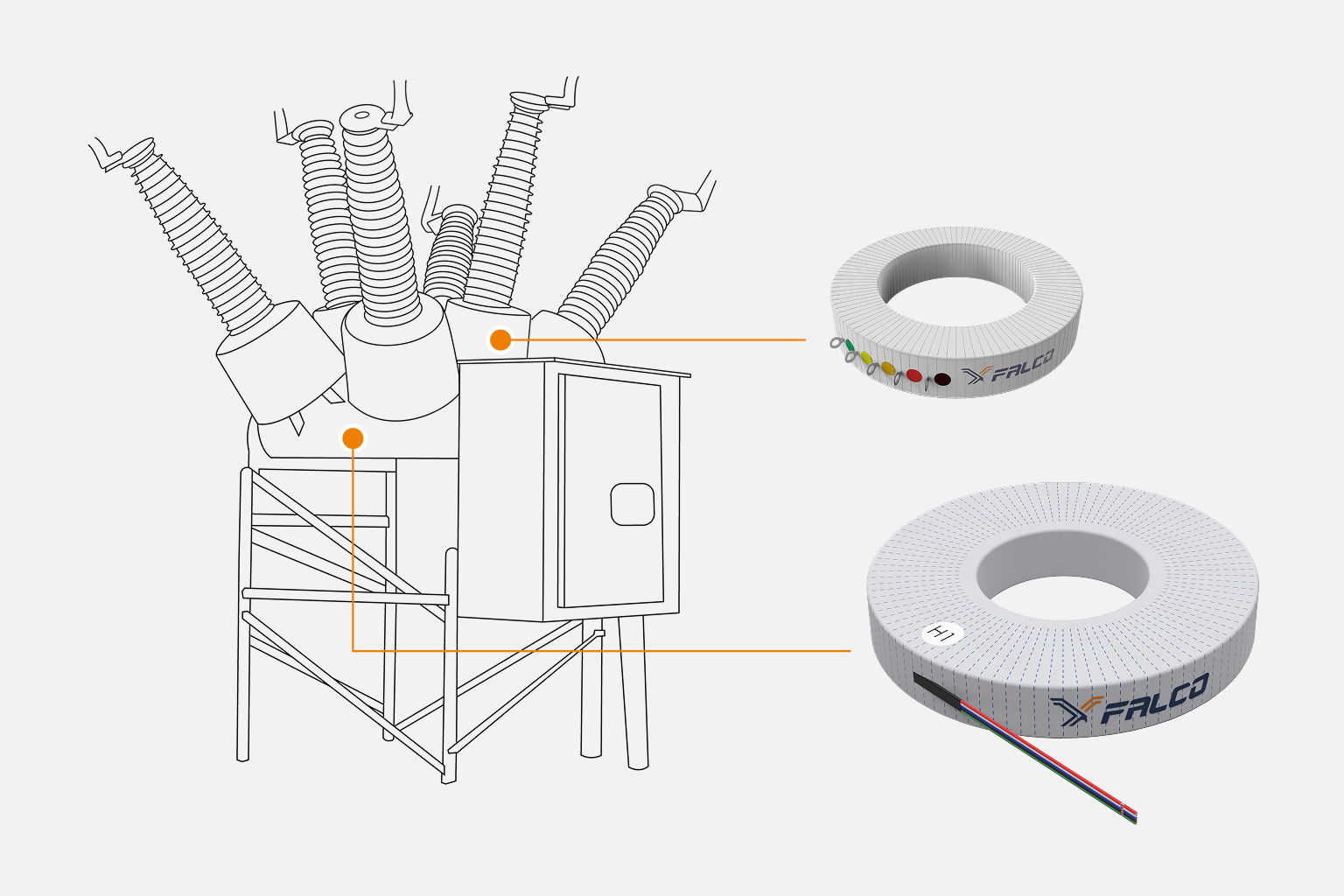

Bushing Current Transformer is specifically designed to be mounted around a transformer bushing. They offer versatile applications in electrical systems due to their design and functionality, allowing for use in diverse environments and applications.

The selection of construction materials is dictated by the insulation methodology employed, with designs tailored for either air-insulated or oil-insulated configurations. Bushing CTs are used in Dead Tank Circuit Breakers gas or oil insulated.

- AC Capability: 50 to 5000Amp

- Frequency: 50-60Hz

- Insulation Class: 0.6-0.72kV

- Applicable Standards: IEEE C57.13 & IEC61869

- Short-time thermal current (ITH) rated 35 x Ipn) at 3s

- Short-time mechanical current (IDYN) rated 2.5 x ITH)

DESIGN CAPABILITIES

- Inner Diameter: 3.0” [76mm] to 25” [635mm]

- Outer Diameter: 4.0” [100mm] to 35” [889mm]

- Relaying Class: up to C1200 per IEEE C57.13; up to 5P20 at 300VA per IEC61869

- Metering Class: down to 0.15S per IEEE C57.13; down to 0.2S per IEC61869

- Operating Temperature: -20°C to 55°C (Dry Type); -20°C to 95°C (Oil Type)

- Rating Factor: up to 4.0 @ 55°C (Dry Type); up to 2.0 @ 95°C (Oil type)

OTHER FEATURES

- Single ratio, dual ratio, multi ratio

- Non standard ratings available

- Customized test reports

- Accuracy class PX per IEC61869

- Laser engraved stainless steel Nameplates

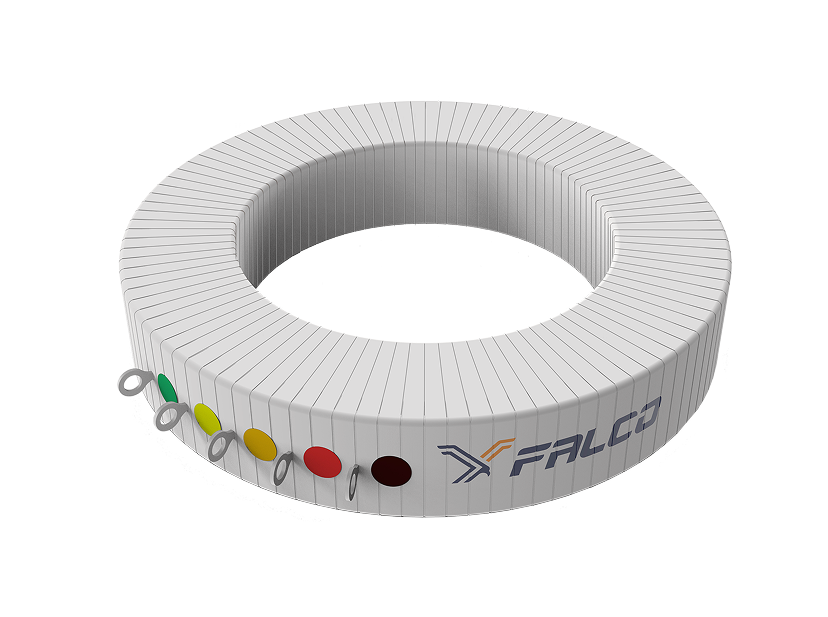

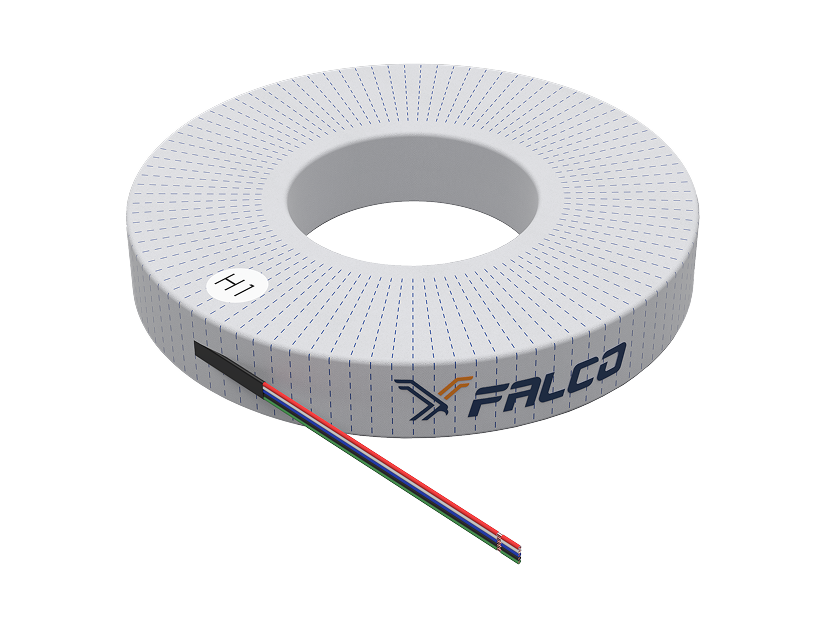

Construction & Design

Bushing Current Transformers are constructed with a toroidal core and a uniformly distributed secondary winding. Insulation material employed is either PET film rated 105°C (dry type) or a combination of kraft paper and cotton tape well suited for oil compatibility (oil type). Core materials include grain-oriented silicon steel for standard applications, with nanocrystalline cores available for high-accuracy requirements. Secondary winding is done with enameled copper wire, rated up to 200°C and proven to be oil resistant.

Terminations & Marking

Dry-type units are typically fitted with M6 ring tongue terminals or PVC/THHN lead wires, while Oil-type units are supplied with FEP or ETFE lead wires rated for higher temperatures and compatible with oil immersion. Each transformer includes a durable polyester serialized nameplate listing key specifications for full traceability. If required, a stainless-steel copy of the nameplate can also be provided.

Packaging & Shipping

To ensure safe delivery, every transformer is packed in sealed wooden crates that protect against moisture and handling. Returnable plastic containers are also available as a sustainable packaging alternative.